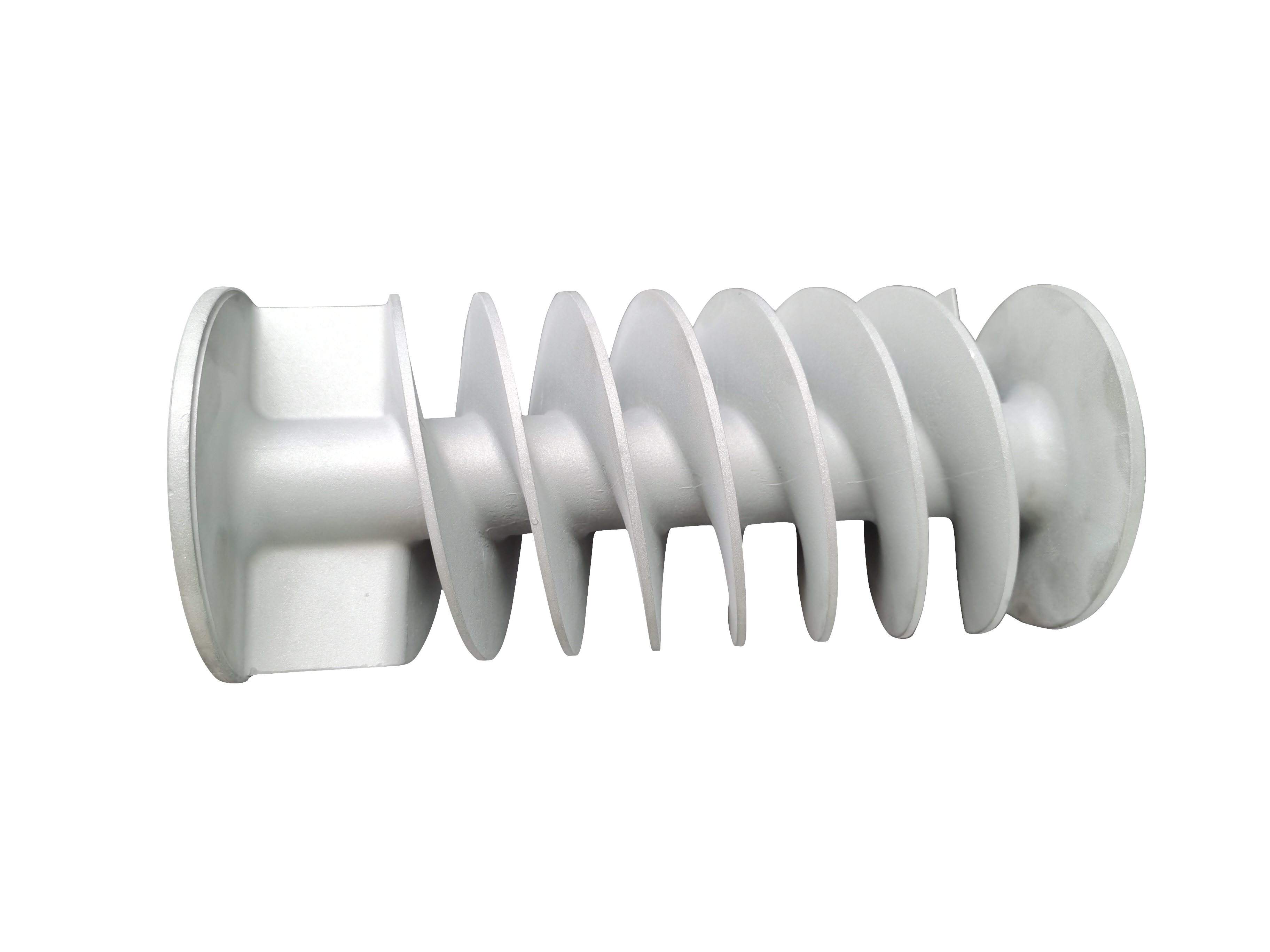

15 Years Factory investment casting CNC Machining Parts form China factory

Product Description

Our Factory

Customized Casting Service

Customized carbon Steel parts , stainless , Aluminum and Iron parts According to customers' drawings

Lead time: 4-6 weeks

Process : Investment casting Stainless

Die casting Aluminum

Sand casting Grey Iron

Added Value service ·Machining

·Heat Treatment

·Finishing

Quality Assurance: 100% inspection

Customized carbon Steel parts , stainless , Aluminum and Iron parts According to customers' drawings

Lead time: 4-6 weeks

Process : Investment casting Stainless

Die casting Aluminum

Sand casting Grey Iron

Added Value service ·Machining

·Heat Treatment

·Finishing

Quality Assurance: 100% inspection

Quality Control

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production---In process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(OQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production---In process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(OQC)

Certifications

Products Description

Investment Casting | Die Casting | Sand Casting | |

Weight | 5g-50kg | 0.5kg-1000kg | 0.5kg-1000kg |

Capability | 150 ton per month | 50 ton per month | 1000 ton per month |

Machining Tolerance | +-0.01-0.03mm | +-0.01-0.03mm | +-0.01-0.03mm |

Cast Material | stainless steel , Carbon steel | Aluminum , alloy | Grey Iron , Aluminum |

Surface Roughness | 6.4 Ra um/254 Ra uinches | 3.2 Ra um/125 Ra uinches | 3.2 Ra um/125 Ra uinches |

other OEM Service | CNC Machining | Surface Treatment | Painting /coating |

We can make brass/steel/stainless steel/aluminum castings with Sand Cast Process, Investment Cast Process, Lost Wax Cast Process,

Water Glass Cast Process,Gravity Cast Process and Die Cast Process.

Sand Casting

Gravity casting

Investment Castng

Lost Wax Casting

Water Glass Casting

Die Casting

Water Glass Cast Process,Gravity Cast Process and Die Cast Process.

Sand Casting

Gravity casting

Investment Castng

Lost Wax Casting

Water Glass Casting

Die Casting

Packing instruction

Our Clients

Why choose us

1) Design assistance and full engineering support .

2) Professional at OEM & ODM parts .

3) Excellent after sales service.

4) Advanced machine tools, CAD/CAM programming software.

5) Prototype machining capabilities.

6) Strict quality control standards with a highly qualified inspection department .

7) Continually upgrading and advancing our equipment to remain competitive .

8) Small quality is also available.

2) Professional at OEM & ODM parts .

3) Excellent after sales service.

4) Advanced machine tools, CAD/CAM programming software.

5) Prototype machining capabilities.

6) Strict quality control standards with a highly qualified inspection department .

7) Continually upgrading and advancing our equipment to remain competitive .

8) Small quality is also available.

FAQs

Q: What do I need for offering a quote ?

A: Please offer us 2D or 3D drawings (with material, dimension, tolerance, surface treatment and other technical requirement etc.)

,quantity, application or samples. Then we will quote the best price within 24h.

Q: What is your MOQ?

A: MOQ depends on our client's needs, besides,we welcome trial order before mass-production.

Q: What is the production cycle?

A: It varies a lot depending on product dimension,technical requirements and quantity. We always try to meet customers'

requirement by adjusting our workshop schedule.

Q: What kind of payment terms do you accept?

A.: T/T, L/C, Escrow, paypal, western union, moneygram etc.

Q: Is it possible to know how is myproduct going on without visiting your company?

A: We will offer a detailed products schedule and send weekly reports with digital pictures and videos which show the machining

progress.

A: Please offer us 2D or 3D drawings (with material, dimension, tolerance, surface treatment and other technical requirement etc.)

,quantity, application or samples. Then we will quote the best price within 24h.

Q: What is your MOQ?

A: MOQ depends on our client's needs, besides,we welcome trial order before mass-production.

Q: What is the production cycle?

A: It varies a lot depending on product dimension,technical requirements and quantity. We always try to meet customers'

requirement by adjusting our workshop schedule.

Q: What kind of payment terms do you accept?

A.: T/T, L/C, Escrow, paypal, western union, moneygram etc.

Q: Is it possible to know how is myproduct going on without visiting your company?

A: We will offer a detailed products schedule and send weekly reports with digital pictures and videos which show the machining

progress.

Product Categories : Investment casting > Investment casting

Premium Related Products

Other Products

Hot Products

Lifting Jack for Well Oil Drilling ExploitationHigh Precision Welding Parts for Power GenerationSteel Stuff Box Cover for Itt GouldsPump Spare Parts for Pump Power EndsCentrifugal Pump Parts Wear Parts Machining PartsLost Wax Casting / Investment Casting Centrifugal Pump ImpellerWear-Resistant Goulds Pump Volute CasingMachining Shaft for Machining PartSand Casting Centrifugal Pump/Water Pump /Chemical Pump Volute CasingStainless Steel/Cast Iron /Vertical Turbine Pump /Multistage Pump BowlsGoulds 3196 Centrifugal Pump Impeller TitaniumANSI Flowserve Durco Stainless Steel Pump ImpellerVertical Turbine Pump DiffuserLost Wax Casting/Investment Casting Durco Pump ImpellerCounter Weight Iron Supplier for Oil & Gas IndustrySand Casting Stainless Steel/Alloy Steel /Carbon Steel Pump Components