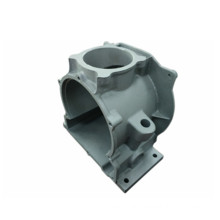

Investment casting Pump parts

Product Description

Manufacturing Process

Silica sol Investment casting is at the heart of our production methodology, allowing us to achieve precision and intricacy in the manufacturing of various components.

Materials Variety

Our capabilities span across a wide range of materials, including stainless Steel, carbon steel, aluminium alloy, alloy steel, copper, cast Iron, ductile iron, and more, ensuring versatility and adaptability to diverse project requirements.

Capacity

With an annual capacity of 8000 tonnes, we can efficiently handle projects of varying scales and complexities.

Standards Compliance: We adhere to stringent industry standards such as ASTM, AISI, BS, DIN, JIS, and NF, ensuring the quality and reliability of our products.

Certification

Our commitment to quality is underlined by certifications including ISO 9001, ISO/TS16949, and AS9100, providing assurance of our adherence to international standards.

Dimension Tolerance

Our advanced manufacturing processes enable us to achieve dimension tolerances ranging from CT4 to CT7, ensuring precise and accurate components.

Surface Roughness

We maintain surface roughness levels between Ra1.6 and Ra3.2, guaranteeing a smooth and high-quality finish for our products.

Casting Weight: Our capabilities extend to casting weights of up to 100kgs, accommodating a wide range of project requirements and component sizes.

Software Expertise

We utilise industry-leading software such as Pro/E, AutoCAD, Solid Work 2005, and CAD/CAM/CAE to ensure efficient and accurate design and specification processes.

Surface Finish Options

Our offerings include a variety of surface finishes such as polishing, rust-proof oil coating, zinc plating, nickel plating, chrome plating, sandblasting, painting, and PVC powder coating, catering to diverse aesthetic and functional requirements.

Precision Machining

Our CNC lathes, milling machines, drilling machines, planning machines, grinding machines, and testing facilities enable us to achieve precise and intricate machining processes, ensuring the highest quality standards for our components.

Proofing and Process Cycles

We offer rapid proofing cycles of 8-15 days, followed by efficient process cycles of the same duration, ensuring timely project completion and delivery.

Complete Manufacturing Solution

At A&M Manufacturing Company Ltd, we offer a comprehensive range of services, including advanced silica sol investment casting processes capable of producing ultra-thin, high-precision, and complex-shaped components in various materials. We utilise a wide range of raw materials, including stainless steel, aluminium alloy, copper, and iron, ensuring versatility in our product offerings. Our continuous improvement in investment casting techniques guarantees superior dimensional tolerances, surface finishes, and product quality, meeting or exceeding national standards across multiple industries such as mining, construction machinery, marine, automotive, and more. We also provide In-house tooling, 3D printing, rapid prototyping and UK stockholding facilities tailored to customers' needs and requirements.

Contact us if you need more details on Precision Aluminium Investment Casting. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Precision Metal Castings、Precision Aluminium Investment Casting. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Investment Casting > Alloy Steel Investment Casting