China professional foundry Supply sand casting motor housing parts for agriculture machinery

Product Description

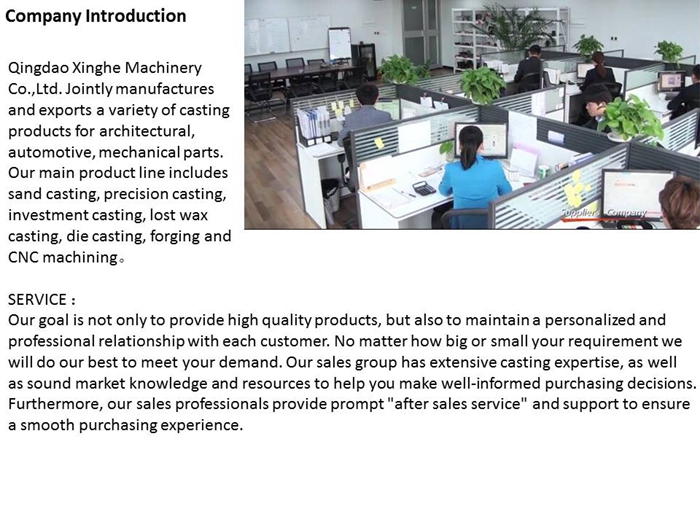

Company introduction

Xinghe is the professional manufacture of Casting products which lies in Qingdao city,Shangdong Province . Our factory was built

in 2005, we have been in the casting business more than 15 years. And we are experienced to deal with all different kinds of

casting products .

Just one point: We are special in Casting Parts

In short: We are such kind one factory that supply casting products according to your samples or your drawings

in 2005, we have been in the casting business more than 15 years. And we are experienced to deal with all different kinds of

casting products .

Just one point: We are special in Casting Parts

In short: We are such kind one factory that supply casting products according to your samples or your drawings

Qingdao Xinghe Machinery Co., Ltd. Jointly manufactures and exports a variety of casting products for architectural, automotive,

mechanical parts. We export to more than 20 countries on 6 continents and have been doing so for more than 10 years.

Our main product line includes Sand casting, precision casting, Die casting, Forging, Stamping, Welding and CNC Machining.

Materials vary from grey Iron , ductile iron, bronze, Aluminum, Steel , stainless steel, and so on.

We have a strong and highly efficient R&D team which can design and make OEM/ODM products according to your ideas and samples.

mechanical parts. We export to more than 20 countries on 6 continents and have been doing so for more than 10 years.

Our main product line includes Sand casting, precision casting, Die casting, Forging, Stamping, Welding and CNC Machining.

Materials vary from grey Iron , ductile iron, bronze, Aluminum, Steel , stainless steel, and so on.

We have a strong and highly efficient R&D team which can design and make OEM/ODM products according to your ideas and samples.

Production Capacity

Material | 1.Sand casting&Gravity casting&Low pressure die casting: A356/A319/A413/ZL101/ZL102/ZL104/ZL107/LM6//LM/20/LM25/EN AC-42100/EN AC-42200/EN AC-43000/ EN AC-43200/EN AC-43300/EN AC-43400/EN AC-44200/EN AC-44300/EN AC-46000/EN AC-46200 2.High pressure die casting: A380/A390/A360/ADC10/ADC12/ENAC-43400/ENAC-44300/ENAC-44400/ ENAC-46000/ENAC-46100/ENAC-46200/ ENAC-46500/ENAC-47100 3.CNC machining casting: 6061-T6/6063-T6 |

Service | Sand casting, Gravity casting, high pressure die casting,low pressure die casting and CNC Machining casting. |

Equipment of Casting | 1. High pressure die casting machining:125T/180T/250T/280T/500T/800T/1250T 2. Gravity casting machine: 5 production lines 3. Low pressure die casting machining: 1 production line 4. Sand casting machine: 6 production lines 5. Degassing equipment and opportunities to refine the material 6. Machining: 5Sets CNC Machines;3 sets Milling machines; 3 setsTurning machines; 10 sets drill and tap machines |

Testing facility | spectrometer, tensile test machine, hardness test machine,CMM dimension report |

Certificate | ISO9001:2008/Rosh/SGS/BV |

Standard | ASTM, DIN,JIS, EN, ISO, GB standards |

Software | Pro/E,UG, Solidworks, Auto CAD, PDF |

Precision machining | CNC turning, milling, drilling, grinding, cutting, reaming and threading |

Product | All kinds of aluminum casting: include automotive parts, railroad parts,medical parts, marine parts, lighting parts, pump body, valve parts,architectural parts and furniture parts so on |

Related Product Recommendation

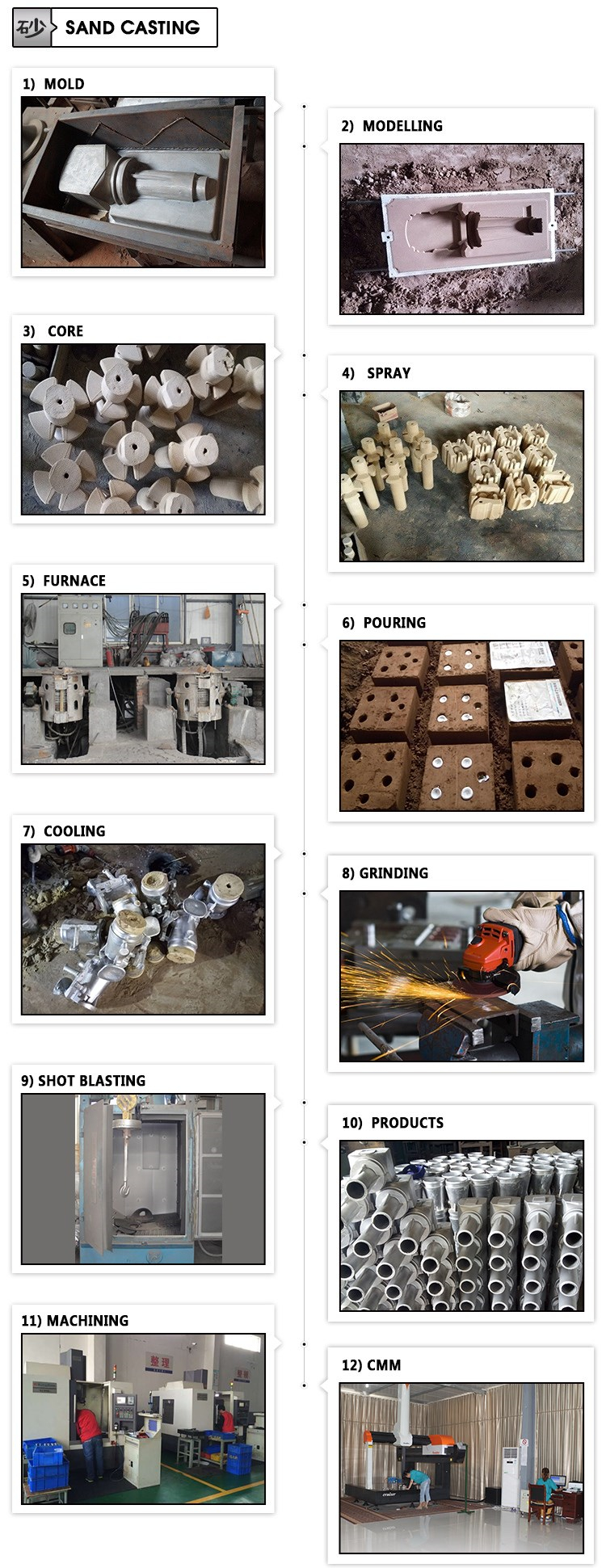

Production Equipment

Inspection Equipment

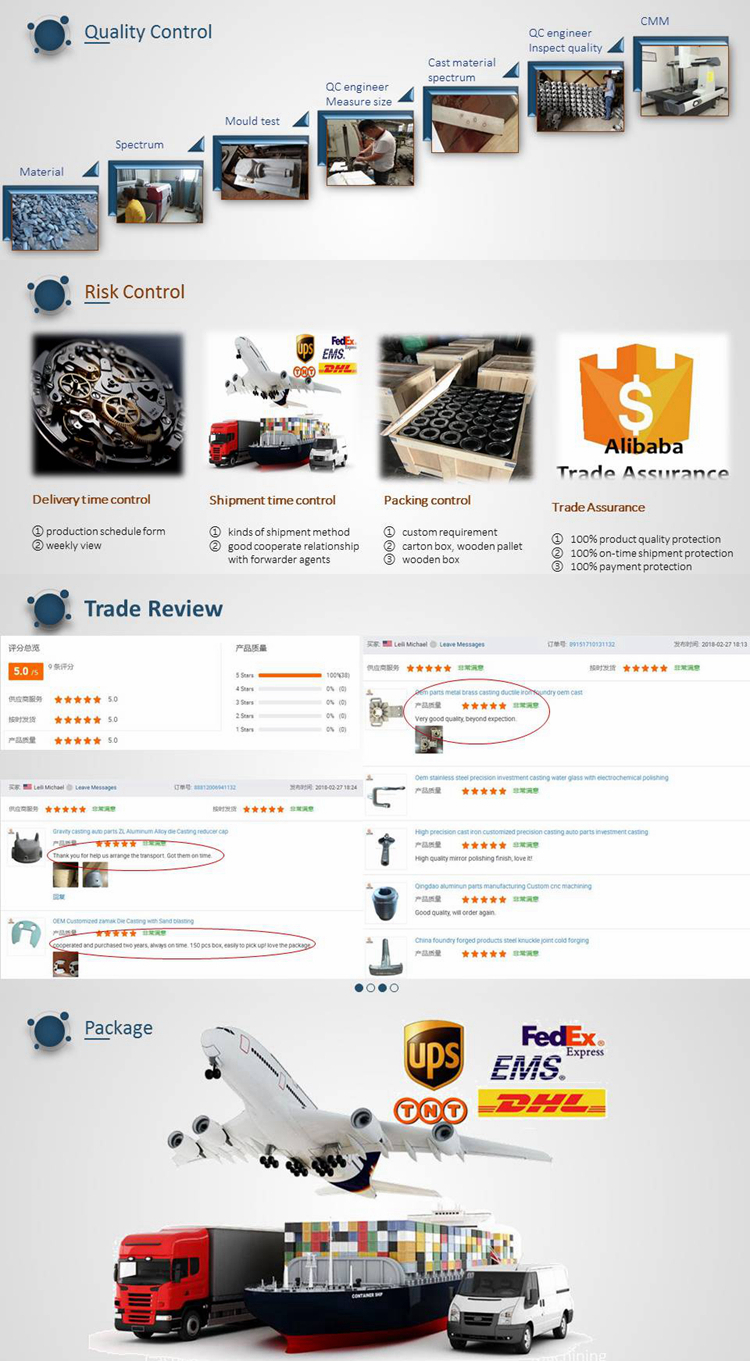

QC process

During many of the procedures and upon completion of all the machining operations, Xinghe Casting performs quality checks to

ensure the manufactured part meets the exact customer specifications.

We use a variety of testing instruments including "go or no-go" gauges (to determine if threads or other dimensions holes are

correct), micrometers, height gauges, calipers, thread gauges, bore gauges and ring gauges. We test and certify these gauges

regularly.

We also have a specialized unit for pressure testing our castings. It measures pressure loss for castings that will be used in

liquid or air applications. This testing and certification is also available to our customers with their shipped product.

Xinghe Casting also has full CMM (Coordinate Measuring Machine) capabilities and can supply this data to our customers with their

1st article reports. This CMM has greatly reduced our time in measuring new and full production parts and allows us to measure

dimensions that would be difficult otherwise.

Specific casting control measures include: Heat Treat Certification, Hardness Testing, First Article Inspection.

About the raw material, it is very important for casting. Before casting, we will do testing bar to check the Chemical composition

and Mechanical properties. In our raw material warehouse, we are doing the marks on each type material. Free from the mistake when

the workers melt the raw material.

ensure the manufactured part meets the exact customer specifications.

We use a variety of testing instruments including "go or no-go" gauges (to determine if threads or other dimensions holes are

correct), micrometers, height gauges, calipers, thread gauges, bore gauges and ring gauges. We test and certify these gauges

regularly.

We also have a specialized unit for pressure testing our castings. It measures pressure loss for castings that will be used in

liquid or air applications. This testing and certification is also available to our customers with their shipped product.

Xinghe Casting also has full CMM (Coordinate Measuring Machine) capabilities and can supply this data to our customers with their

1st article reports. This CMM has greatly reduced our time in measuring new and full production parts and allows us to measure

dimensions that would be difficult otherwise.

Specific casting control measures include: Heat Treat Certification, Hardness Testing, First Article Inspection.

About the raw material, it is very important for casting. Before casting, we will do testing bar to check the Chemical composition

and Mechanical properties. In our raw material warehouse, we are doing the marks on each type material. Free from the mistake when

the workers melt the raw material.

Package&Shipping

Why choose us

1. With more than 15 years in Aluminum casting;

2. Have four casting types;

3. Near QingdaoPort,Near Air port.

4. From Casting to Finished surface, Owned casting,polishing and plating workshops, We can offer Good quality and strict delivery time.

5. With samples and order: We can offer dimension report,Chemical composition and Mechanical properties

6. Control material with spectral and thermal analysis equipment (density and processing)

7. Spectral analysis of raw material and liquid melt,batch before casting.

Thank you to browse our online showroom. If you want to know more about our factory, pls visit our website https://www.qd-xinghe.com/

And then email us your inquiry today, we will send you price list in 24 hours.

Product Categories : Sand casting > Sand casting

Premium Related Products

Other Products

Hot Products

Lifting Jack for Well Oil Drilling ExploitationHigh Precision Welding Parts for Power GenerationSteel Stuff Box Cover for Itt GouldsPump Spare Parts for Pump Power EndsCentrifugal Pump Parts Wear Parts Machining PartsLost Wax Casting / Investment Casting Centrifugal Pump ImpellerWear-Resistant Goulds Pump Volute CasingMachining Shaft for Machining PartSand Casting Centrifugal Pump/Water Pump /Chemical Pump Volute CasingStainless Steel/Cast Iron /Vertical Turbine Pump /Multistage Pump BowlsGoulds 3196 Centrifugal Pump Impeller TitaniumANSI Flowserve Durco Stainless Steel Pump ImpellerVertical Turbine Pump DiffuserLost Wax Casting/Investment Casting Durco Pump ImpellerCounter Weight Iron Supplier for Oil & Gas IndustrySand Casting Stainless Steel/Alloy Steel /Carbon Steel Pump Components